ASTM D1596 Foam Test Methods

Test method ASTM D1596 is referenced by ASTM D3575. It is used to determine the shock absorbing characteristics of unrestrained package cushioning mounted on a rigid testing surface and shocked with a known weight. In simpler terms, it is the method used in the laboratory to develop dynamic cushioning curves. This test method cannot be used with materials which will not hold together when impacted by a platen drop – such as loose-fill or many foam-in-place urethane formulations.

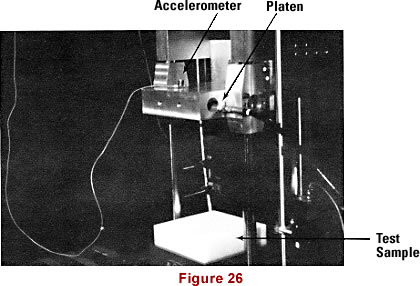

Dynamic cushioning data obtained by this method may not reflect the actual cushioning that will occur inside a completed package. This is because the test method does not account for the internal cushioning properties of the products being packaged, the effects of product restraint and friction inside packages, or the cushioning contribution of the outer container. These factors tend to add to product protection. Also remember that each dynamic cushioning curve you develop applies only for the cushioning material, material thickness, drop height, and number of impacts you use during testing. Figure 26 shows an example of the type of equipment used for the development of dynamic cushioning curves. Note the thimble-like device mounted on the top of the metal platen. This is the accelerometer, which is connected by the thin wire to a computer, oscilloscope or other data acquisition device. The accelerometer measures the mechanical shock experienced by the platen as it impacts the test sample. Weights can be added to the platen to test the different static loadings.

Dynamic cushioning data obtained by this method may not reflect the actual cushioning that will occur inside a completed package. This is because the test method does not account for the internal cushioning properties of the products being packaged, the effects of product restraint and friction inside packages, or the cushioning contribution of the outer container. These factors tend to add to product protection. Also remember that each dynamic cushioning curve you develop applies only for the cushioning material, material thickness, drop height, and number of impacts you use during testing. Figure 26 shows an example of the type of equipment used for the development of dynamic cushioning curves. Note the thimble-like device mounted on the top of the metal platen. This is the accelerometer, which is connected by the thin wire to a computer, oscilloscope or other data acquisition device. The accelerometer measures the mechanical shock experienced by the platen as it impacts the test sample. Weights can be added to the platen to test the different static loadings.